Rotary Screw Air Compressors

Rotary Screw Air Compressors

A basic introduction to rotary screw air compressors:

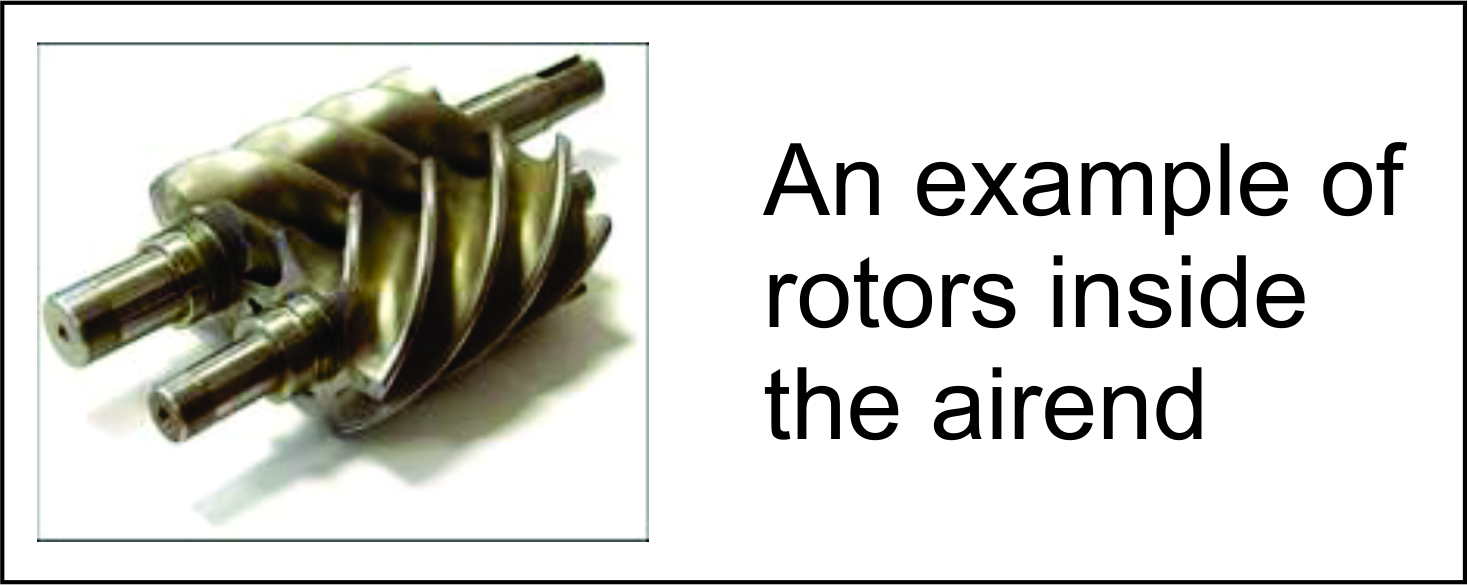

Instead of pistons and valves producing the compressed air, rotary screw air compressors use male and female rotors with an extremely small amount of space between them. Air comes in through the intake and mixes with the lubricant and spins through the rotors. Once the air and lubricant pass through the rotors, they are separated through a filter. The air then goes out to the air system or tank and the lubricant is collected in a sump. The larger the rotors, the more volume of air (CFM) can be produced. Since the rotors do not touch, they are under much less stress than a piston air compressor and it can run 24 hours per day, 7 days per week if needed, where a piston type has a maximum duty cycle of 75% and many times lower. (Some manufacturers claim 100%, but that is simply marketing and they will typically have small print saying to allow up to 30% for leaks and such)

Unlike a piston air compressor, most will not build up to pressure and cut off, it will run unloaded (venting air to atmosphere) for a period of time and once the air demand picks back up, it will start putting the air in the system again. If the air demand is not enough to keep it running, it will eventually shut down. In the right application, this will save energy (and money) by not having the "hard start" of the motor multiple times per hour.

Thank you to CP Compressors for the Images

When should you choose a rotary screw over a piston air compressor?

Rotary screw air compressors are fantastic machines in the right application. Although they are very popular because they typically are very quiet, a rotary screw air compressor may not always be the best fit and actually could be a huge mistake.

When choosing a rotary screw, you want to size it as close to your air demand, in CFM, as possible. If you oversize it, it simply will not run enough.

Rotary screw air compressor are designed to run 100% of the time. Industrial and body shop applications are typically a great fit for a rotary screw because there is typically a consistent demand for air. Automotive shops can be hit and miss especially if it is a smaller shop that doesn't use a tremendous amount of air.

When considering a rotary screw air compressor, you will want to know that you will keep it running. If a rotary screw does not run enough, the lubricant will not burn off any moisture that is mixed in with the air and in the worst cast scenario, it could cause the air end to fail, which would be a costly mistake.

So, when considering which type of compressor to choose, determine how much air you need Sizing Guide and if that it will be a constant demand, at least most of your work day.

As always, we are glad to help you with your decision. We want you to be satisfied with any purchase you make from us, please let us know how we can help. Contact Us

Click here for our Rotary Screw Compressors